Odlewnia Stopów Niklu, Odlewy Stopów Kobaltu, Nadstopy, CNC

Treść ogłoszenia

Odlewnia SOBOWIDZ - Odlewnia Stopów Niklu, Odlewy Stopów Kobaltu,

Nadstopy, CNC

rok założenia 1983

COBALT ALLOYS - NICKEL CASTINGS

TITAN CASTINGS - SUPERALLOYS

CAST STEELS - CAST IRONS

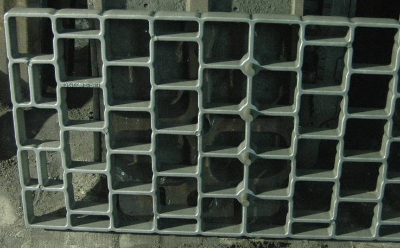

SAND CASTINGS - GRAVITY DIE CASTINGS - CENTRIFUGAL CASTINGS

SHELL CASTINGS - LOST WAX CASTINGS - INVESTMENT PRECISION CASTINGS

ENGINEERING CASTINGS

COBALT CASTINGS,

Cobalt Foundry. SAE UMCo-51. Co50, Co40, Co20, Co-base materials,

cobalt alloy castings, UMCo51,

SAE UMCo-50, 2.4778, G-CoCr28 acc. to EN 10295: 2002, SEW 471, DIN 17465,

UMCo50Nb, UMCo-20,

UNS R30075 (ASTM F75, ISO 5832-4) Co-Cr-Mo Alloy,

Conicro 5010 W, Haynes 25,

Conicro 4023 W, Haynes 188,

Cobalt – Chromium, Co-Cr, cobalt casting alloys, furnace riders,

Cobalt – Chromium – Niobium, Co-Cr-Nb, Cobalt-Based Alloy Castings,

Cobalt – Chromium – Tungsten, Co-Cr-W, Alnico alloys, Al-Ni-Co, Alniko,

STELLITE 1, STELLITE 3, STELLITE 4, STELLITE 6, STELLITE 12, STELLITE 20, STELLITE 21, STELLITE 31,

STELLITE 190, STELLITE 238, STELLITE 306, STELLITE 694,

STELLITE F, STELLITE SF1, STELLITE SF6, STELLITE SF12, STELLITE SF20, TRIBALOY T400, TRIBALOY T800,

DELORO 15, DELORO 22, DELORO 40, DELORO 50, DELORO 60, DELORO 625, NISTELLE C, TRIBALOY T700, SL28CO5,

heat resistant superalloys HRSA

NICKEL CASTINGS , Nickel base alloys e.g.

Alloy 657 - 2.4680 - G-NiCr50Nb,

NA22H - 2.4879 - G-NiCr28W,

Nickel Alloy 617 - 2.4663 - ISO NiCr22Co12Mo9, DIN NiCr23Co12Mo, ASTM UNS N06617, NA50, Inco-nel 617, Ni-cro-fer 5520 Co,

Alloy 601 - 2.4851 - NiCr23Fe,

Alloy 602CA - 2.4633 - NiCr25FeAlY,

2.4815 - G-NiCr15,

EN 2.4654 - NiCr20Co13Mo4Ti3Al,

supperalloys, NICKEL ALLOY CASTINGS, invar, chromonikiel, nichrome,

ASTM A494 CW12MW,

ASTM A494 CW6M,

ASTM A494 CU5MCuC,

ASTM A494 CX2MW,

ASTM A494 CY40,

ASTM A494 CZ100,

ASTM A494 N12MV,

ASTM A494 N7M,

ASTM A494 CW6MC,

ASTM A494 CW2M,

Nickel – Copper :

ASTM A494 M30C,

ASTM A494 M35-1,

ASTM A494 M35-2,

BS 3071 NA1,

BS 3071 NA2,

BS 3071 NA3,

NiCr20Ti, Nimonic 75, Nicrofer 7520, AKN 20, EI 435,

NiCr20TiAl, AKNC, Nimonic 80A, Nicrofer 7520Ti,

NiCr15Fe, Inconel 600, Nicrofer 7216,

NiCr23Fe, Nicrofer 6023,

NiCo20Cr20MoTi, Nimonic 263, Nicrofer 5120CoTi, C-263,

NiCr20Co16TiAl, Nimonic 90, EN 2295,

NiCo20Cr15MoAlTi, Nimonic 105, EN 2180

NiCr15Co14AlMoTi, Nimonic 115,

alloy 625, NiCr22MoNb,

alloy 718, NiCr19NbMo,

invar 36 / 1.3912 / Alloy 36 / UNS K93600 / EN Ni36

EUZONIT B 2, EUZONIT C 4, EUZONIT G 60, EUZONIT G 4810, EUZONIT GX,

MA754, LVN4,

B - 1900, MAR-M 246, MAR-M 247, LVN-9, ŽS 6K, ŻS-6U / ŻS6U,

2.4060 / nickel NP2 according to Russian standard GOST,

Nickel – Molybdenum,

Nickel – Chromium,

Nickel – Molybdenum – Chromium,

Galling resistant Nickel Alloy,

EN 10302 : Creep resisting steels, nickel and cobalt alloys

Non Galling Castings,

TITAN CASTINGS as

e.g. alloy 3.7031 according to DIN 17865

Staliwo Narzędziowe, chromowe, węglowe,

L210H21, L210H21NM, L210H21S (wg PN-90/H-83161), L210H21M, odlewy staliwne HB > 500

L120G13 wg PN-88/H-83160, L35H17N2M, 20MnV6, G26CrMo4,

L100H6M (HB 495 - 601) wg PN-88/H-83160, L40H5MF, L45HN2MF wg PN-90/H-83161,

L40H5M, G25CrMo4, G34CrMo4, 25HM, 34HM, 300M, Chromosil LC, Utaloy 700, Climax 15-3 i inne

GS42CrMo4, L40HM (HB min. 400), 40HM,

L65HNM, L70H2GNM, L75HMF, L90HMF wg PN-90/H-83161,

L150HSM, L155HNM, L180HNM, L200HNM, L200HSN1VT,

L40H5M, GS-25CrMo4, 25HM,

L180H20F (HB min. 480 - kule staliwne dla cementowni), L35H17N2M (PN-90/H-83161, np. rozwłókniacze dla przemysłu papierniczego, L40H5MF, L45HN2MF, L65HNM, L75HMF, L100H2M, L120HWMF (HB min. 320), L120HNMF,

L190H32N6 wg BN-68/0631-03 - Stale i staliwa narzędziowe stosowane w hutnictwie |elaza.

Rury trudnościeralne stalowe, tuleje, wkładki trudnościeralne wspawowywane do rur, Odlewy napawane stopem trudnościeralnym,

staliwo i żeliwo chromowo-molibdenowe trudnościeralne: L210H21NM, ZlCr25Mo2, Zl350Cr20Mo2

** Staliwo narzędziowe PN-90/H-83161:

staliwa chromowo-niklowo-molibdenowe

L35H17N2M, L65HNM, L210H21NM

staliwa chromowo-molibdenowo-wanadowe

L40H5MF, L75HMF

staliwa chromowo-niklowo-molibdenowo-wanadowe L45HN2MF, L120HNMF;

L45G - Staliwo manganowe

L100H2M - Staliwo chromowo-molibdenowe

L120HWMF - Staliwo chromowo-wolframowo-molibdenowo-wanadowe

L210H21 - Staliwo chromowe

L70H2GNM

PN-H-85020:1984 (aktualnie nieobowiązująca, zastąpiona przez normy europejskie, definiujące nowy system oznaczeń) :

stale narzędziowe węglowe wg PN : N5, N6, N7, N7E, N8, N8E, N9, N9E, N10, N10E, N11, N11E, N12, N12E, N13, N13E.

PN-H-85020 (1984) Stal węglowa narzędziowa -- Gatunki

PN-H-94054 (1983) - Forged bars of carbon and alloy tool steels for cold work

stale narzędziowe - EN ISO 4957: 2000 Tool steels :

1.1520 C70U

1.1525 C80U

1.1535 C90U

1.1545 C105U

1.1555 C120U

1.1730 C45U

1.2067 102Cr6

1.2080 X210Cr12

1.2083 X40Cr14

1.2162 21MnCr5

1.2302 35CrMo7

1.2316 X38CrMo16

1.2343 X37CrMoV5-1

1.2344 X40CrMoV5-1

1.2355 50CrMoV13-15

1.2363 X100CrMoV5

1.2365 32CrMoV12-28

1.2367 X38CrMoV5-3

1.2379 X153CrMoV12

1.2436 X210CrW12

1.2549 50WCrV8

1.2550 60WCrV8

1.2581 X30WCrV9-3

1.2605 X35CrWMoV5

1.2661 38CrCoWV18-17-17

1.2714 55NiCrMoV7

1.2738 40CrMnNiMo8-6-4

1.2767 45NiCrMo16

1.2824 70MnMoCr8

1.2825 95MnWCr5

1.2834 105V

1.2842 90MnCrV8

1.3207 HS10-4-3-10

1.3243 HS6-5-2-5

1.3244 HS6-5-3-8

1.3247 HS2-9-1-8

1.3325 HS0-4-1

1.3326 HS1-4-2

1.3327 HS1-8-1

1.3333 HS3-3-2

2025.11.30

Nadstopy, CNC

rok założenia 1983

COBALT ALLOYS - NICKEL CASTINGS

TITAN CASTINGS - SUPERALLOYS

CAST STEELS - CAST IRONS

SAND CASTINGS - GRAVITY DIE CASTINGS - CENTRIFUGAL CASTINGS

SHELL CASTINGS - LOST WAX CASTINGS - INVESTMENT PRECISION CASTINGS

ENGINEERING CASTINGS

COBALT CASTINGS,

Cobalt Foundry. SAE UMCo-51. Co50, Co40, Co20, Co-base materials,

cobalt alloy castings, UMCo51,

SAE UMCo-50, 2.4778, G-CoCr28 acc. to EN 10295: 2002, SEW 471, DIN 17465,

UMCo50Nb, UMCo-20,

UNS R30075 (ASTM F75, ISO 5832-4) Co-Cr-Mo Alloy,

Conicro 5010 W, Haynes 25,

Conicro 4023 W, Haynes 188,

Cobalt – Chromium, Co-Cr, cobalt casting alloys, furnace riders,

Cobalt – Chromium – Niobium, Co-Cr-Nb, Cobalt-Based Alloy Castings,

Cobalt – Chromium – Tungsten, Co-Cr-W, Alnico alloys, Al-Ni-Co, Alniko,

STELLITE 1, STELLITE 3, STELLITE 4, STELLITE 6, STELLITE 12, STELLITE 20, STELLITE 21, STELLITE 31,

STELLITE 190, STELLITE 238, STELLITE 306, STELLITE 694,

STELLITE F, STELLITE SF1, STELLITE SF6, STELLITE SF12, STELLITE SF20, TRIBALOY T400, TRIBALOY T800,

DELORO 15, DELORO 22, DELORO 40, DELORO 50, DELORO 60, DELORO 625, NISTELLE C, TRIBALOY T700, SL28CO5,

heat resistant superalloys HRSA

NICKEL CASTINGS , Nickel base alloys e.g.

Alloy 657 - 2.4680 - G-NiCr50Nb,

NA22H - 2.4879 - G-NiCr28W,

Nickel Alloy 617 - 2.4663 - ISO NiCr22Co12Mo9, DIN NiCr23Co12Mo, ASTM UNS N06617, NA50, Inco-nel 617, Ni-cro-fer 5520 Co,

Alloy 601 - 2.4851 - NiCr23Fe,

Alloy 602CA - 2.4633 - NiCr25FeAlY,

2.4815 - G-NiCr15,

EN 2.4654 - NiCr20Co13Mo4Ti3Al,

supperalloys, NICKEL ALLOY CASTINGS, invar, chromonikiel, nichrome,

ASTM A494 CW12MW,

ASTM A494 CW6M,

ASTM A494 CU5MCuC,

ASTM A494 CX2MW,

ASTM A494 CY40,

ASTM A494 CZ100,

ASTM A494 N12MV,

ASTM A494 N7M,

ASTM A494 CW6MC,

ASTM A494 CW2M,

Nickel – Copper :

ASTM A494 M30C,

ASTM A494 M35-1,

ASTM A494 M35-2,

BS 3071 NA1,

BS 3071 NA2,

BS 3071 NA3,

NiCr20Ti, Nimonic 75, Nicrofer 7520, AKN 20, EI 435,

NiCr20TiAl, AKNC, Nimonic 80A, Nicrofer 7520Ti,

NiCr15Fe, Inconel 600, Nicrofer 7216,

NiCr23Fe, Nicrofer 6023,

NiCo20Cr20MoTi, Nimonic 263, Nicrofer 5120CoTi, C-263,

NiCr20Co16TiAl, Nimonic 90, EN 2295,

NiCo20Cr15MoAlTi, Nimonic 105, EN 2180

NiCr15Co14AlMoTi, Nimonic 115,

alloy 625, NiCr22MoNb,

alloy 718, NiCr19NbMo,

invar 36 / 1.3912 / Alloy 36 / UNS K93600 / EN Ni36

EUZONIT B 2, EUZONIT C 4, EUZONIT G 60, EUZONIT G 4810, EUZONIT GX,

MA754, LVN4,

B - 1900, MAR-M 246, MAR-M 247, LVN-9, ŽS 6K, ŻS-6U / ŻS6U,

2.4060 / nickel NP2 according to Russian standard GOST,

Nickel – Molybdenum,

Nickel – Chromium,

Nickel – Molybdenum – Chromium,

Galling resistant Nickel Alloy,

EN 10302 : Creep resisting steels, nickel and cobalt alloys

Non Galling Castings,

TITAN CASTINGS as

e.g. alloy 3.7031 according to DIN 17865

Staliwo Narzędziowe, chromowe, węglowe,

L210H21, L210H21NM, L210H21S (wg PN-90/H-83161), L210H21M, odlewy staliwne HB > 500

L120G13 wg PN-88/H-83160, L35H17N2M, 20MnV6, G26CrMo4,

L100H6M (HB 495 - 601) wg PN-88/H-83160, L40H5MF, L45HN2MF wg PN-90/H-83161,

L40H5M, G25CrMo4, G34CrMo4, 25HM, 34HM, 300M, Chromosil LC, Utaloy 700, Climax 15-3 i inne

GS42CrMo4, L40HM (HB min. 400), 40HM,

L65HNM, L70H2GNM, L75HMF, L90HMF wg PN-90/H-83161,

L150HSM, L155HNM, L180HNM, L200HNM, L200HSN1VT,

L40H5M, GS-25CrMo4, 25HM,

L180H20F (HB min. 480 - kule staliwne dla cementowni), L35H17N2M (PN-90/H-83161, np. rozwłókniacze dla przemysłu papierniczego, L40H5MF, L45HN2MF, L65HNM, L75HMF, L100H2M, L120HWMF (HB min. 320), L120HNMF,

L190H32N6 wg BN-68/0631-03 - Stale i staliwa narzędziowe stosowane w hutnictwie |elaza.

Rury trudnościeralne stalowe, tuleje, wkładki trudnościeralne wspawowywane do rur, Odlewy napawane stopem trudnościeralnym,

staliwo i żeliwo chromowo-molibdenowe trudnościeralne: L210H21NM, ZlCr25Mo2, Zl350Cr20Mo2

** Staliwo narzędziowe PN-90/H-83161:

staliwa chromowo-niklowo-molibdenowe

L35H17N2M, L65HNM, L210H21NM

staliwa chromowo-molibdenowo-wanadowe

L40H5MF, L75HMF

staliwa chromowo-niklowo-molibdenowo-wanadowe L45HN2MF, L120HNMF;

L45G - Staliwo manganowe

L100H2M - Staliwo chromowo-molibdenowe

L120HWMF - Staliwo chromowo-wolframowo-molibdenowo-wanadowe

L210H21 - Staliwo chromowe

L70H2GNM

PN-H-85020:1984 (aktualnie nieobowiązująca, zastąpiona przez normy europejskie, definiujące nowy system oznaczeń) :

stale narzędziowe węglowe wg PN : N5, N6, N7, N7E, N8, N8E, N9, N9E, N10, N10E, N11, N11E, N12, N12E, N13, N13E.

PN-H-85020 (1984) Stal węglowa narzędziowa -- Gatunki

PN-H-94054 (1983) - Forged bars of carbon and alloy tool steels for cold work

stale narzędziowe - EN ISO 4957: 2000 Tool steels :

1.1520 C70U

1.1525 C80U

1.1535 C90U

1.1545 C105U

1.1555 C120U

1.1730 C45U

1.2067 102Cr6

1.2080 X210Cr12

1.2083 X40Cr14

1.2162 21MnCr5

1.2302 35CrMo7

1.2316 X38CrMo16

1.2343 X37CrMoV5-1

1.2344 X40CrMoV5-1

1.2355 50CrMoV13-15

1.2363 X100CrMoV5

1.2365 32CrMoV12-28

1.2367 X38CrMoV5-3

1.2379 X153CrMoV12

1.2436 X210CrW12

1.2549 50WCrV8

1.2550 60WCrV8

1.2581 X30WCrV9-3

1.2605 X35CrWMoV5

1.2661 38CrCoWV18-17-17

1.2714 55NiCrMoV7

1.2738 40CrMnNiMo8-6-4

1.2767 45NiCrMo16

1.2824 70MnMoCr8

1.2825 95MnWCr5

1.2834 105V

1.2842 90MnCrV8

1.3207 HS10-4-3-10

1.3243 HS6-5-2-5

1.3244 HS6-5-3-8

1.3247 HS2-9-1-8

1.3325 HS0-4-1

1.3326 HS1-4-2

1.3327 HS1-8-1

1.3333 HS3-3-2

2025.11.30